Sertlik Ölçüm Cihazı

Kalem Sertlik Ölçüm Cihazı

This instrument offers an easy method for the determination of film hardness for coating applied to a flat substrate. The pencil lead, prepared beforehand by rubbing it on fine abrasive paper(400),is maintained at an angle of 45º and pushed with uniform pressure onto the sample, either leaving a superficial trace or causing destruction down to the substrate. It complies with the requirements of ASTM D 3363, ISO 15184.

Main Technical Parameters

■ Three points are touched on the tested surface (roller、pencil lead)

■ The angle between pencil and the tested surface: 45°

■ Pressure of pencil lead :500g/750g/765g/1000g

■ Packing List:

① Pencil Tester, Body

② 1 Set of Pencils (12):-4B-3B-2B-B-HB-F-H-2H-3H-4H-5H-6H.

③ Special Pencil Sharpener

④ Abrasive Paper, 400 grade grit.

⑤ Spirit bubble

⑥ Rubber

⑦ Certificate of conformity or Calibration (if requested)

Pendulum Sertlik Ölçüm Cihazı

A pendulum resting on a coating surface is set into oscillation and the time for the oscillation amplitude to decrease by an amount specified in this International Standard is measured. The shorter the damping time, the lower the hardness.

Two test procedures are considered in some detail, namely those of König and Persoz. (The Persoz and König methods differ by the period and amplitude of the oscillation. The Persoz test measures the time taken for the amplitude of oscillation to decrease from 12° to 4°; the König from 6° to 3°.)

The instruments embody the same principle — that the amplitude of oscillation of a pendulum touching a surface decreases more rapidly the softer the surface — but differ in respect of dimensions, period and amplitude of oscillation.

BGD 509 Pendulum Hardness Tester is the newest product which can be used in accordance with the following National and International Standards: ISO 1522 which supersedes ASTM D4355; BS 3900-E5; DIN 53157; NBN T22-105; NF T30-016.

It’s a simple to use instrument and can be supplied in one of three model types: Persoz, König, and Persoz and König combined

Features

◆ Automatic counter range:0~999

◆ High precision machined parts (Pendulum) ensure a repeatable and comparable testing result.

◆ Can change two test procedure: König or Persoz test

◆ Humanistic LCD Operator Interface

◆ Release Pendulum with shutter release, can get more accuracy test result.

◆ Mount specimen automatically with elevating work platform can mount, easily and conveniently

◆ Can record automatically the time or times for the amplitude of swing to decrease from one angle to other angle and stop testing automatically.

◆ Record the data with two light sensitive sensors

◆ Can select record mode freely: Timing mode or counting mode.

◆ Single piece glass enclosure reduces the effects of air flow on final results..

Main Technical Parameters

|

Ordering Information → Technical Item ↓ |

BGD 509/K |

BGD 509/P |

BGD 509/K+P |

|

Pendulum |

König |

Persoz |

König+ Persoz |

|

Weight |

200g±0.2 |

500g±0.1 |

200g±0.2/500g±0.1 |

|

Ball Diameter |

5mm(0.2in) |

8mm(0.3in) |

5mm/8mm |

|

Deflection Start |

6º |

12º |

6º/12º |

|

Deflection End |

3º |

4º |

3º/4º |

|

Period of Oscillation |

1.4s |

1s |

1.4s/1s |

|

Damping Time on Glass |

250±10s |

430±10s |

250±10s/430±10s |

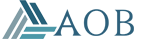

Buchholz Indentation Sertlik Testi

BGD 510 Buchholz IndentationTester is a reliable test method for evaluation of indentation resistance of plastic deformable coatings.A beveled disc with a sharp edge is applied onto the test surface under a constant 500g. Test load provided by a steel block holder. The trace left after 30 s. Load is measured with a 20X magnification illuminated microscope. The length of the indentationis inversely proportional to the hardness.

◆ Conform with Standard ISO 2815

◆ Stainless steel block

◆ Circular tool is a double cone block

◆ Circular tool and support of hard metal

◆ Marking triangle for precise positioning.

◆ 20xmagnification with graduated scale to measure indentation length.

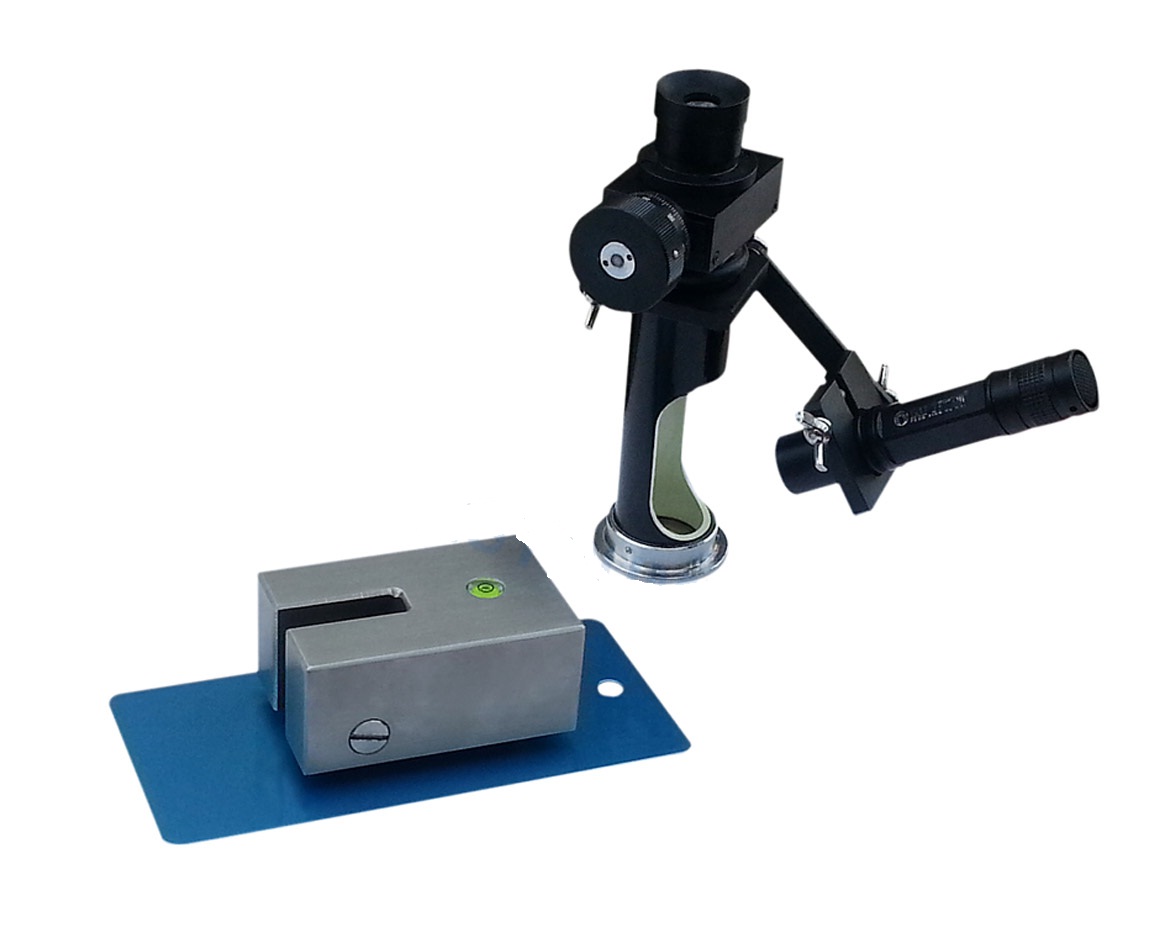

Otomatik Çizik Testi

Features:

◆ Working tablecan be moved left and right—convenient for measuring different areas in thesame panel

◆ Sound-light Alarm system for puncturing through sample panel---more visual

◆ High hardness material needle-more durable

This machine complies with BS 3900;E2, ISO 1518 .Also available, loop stylus version BS 3900 ; E17/ISO 12137-1. N.B. Other specifications available ASTM D5178,D2197

Main Technical Parameters:

■ Motor:60W 220V 50HZ

■ Mass of weights:50g-2500g

■ Diameter of an indentor with a half-spherical end:1mm

■ Max Panel size:100×150×1.6mm(0.3 mm coating)

■ Overall dimensions:380×300×180mm

■ Weight:25kg

■ Ordering Information:BGD 520--- Automatic Scratch Tester

Otomatik Shore Sertlik Testi

Standards: DIN53505, ASTMD2240, ISO7619, JISK7215

Shore A is designed to measure the penetration hardness of rubber, elastomers and other rubber like substances such as neoprene, silicone, and vinyl. It can also be used for soft plastics, felt, leather and similar materials.

Shore C is designed for various foam and sponge.

Shore D is designed for plastics, Formica, Epoxies and Plexiglas.

Main Technical Parameters

■ Measurement range:0-100HA(HC/HD)

■ Measurement deviation:<1%H

■ Resolution: 0.1

■ Power supply: 4x1.5V AAA (UM-4) battery

■ Battery indicator: low battery indicator

■ Dimensions: 162x65x38mm

■ Weight (not including probe):173g