Diğerleri

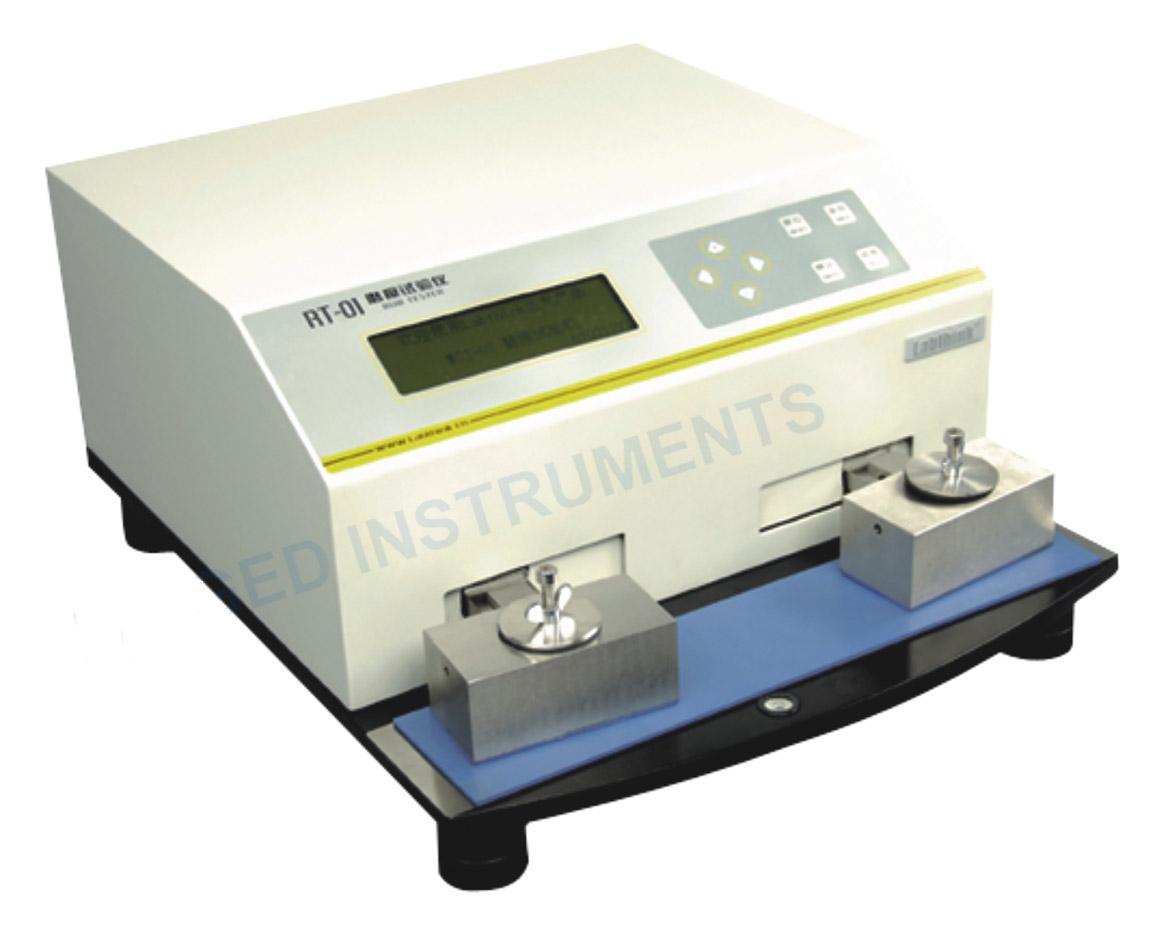

Rezistans Ovma Testi

BGD 630 Rub Resistance Tester is applicable in rub abrasion resistance test of printing works, light sensitive layer of PS boards, and coating layers of relative products. It can help users to analyze the affairs of lower abrasion assistance, ink layer falling-off, lower printable of PS boards, and rigid of coating layers of other products.

Features:

◆ Wide voltage range design(110-220V;50/60Hz), good compatibility

◆ Adjustable variable speed:5~150 c.p.m

◆ Micro-computer control, LCD displays data.

◆ Parameters set freely and permanently storage.

◆ Control and resolve the problems of low bad abrasion resistance and easy falling-off of ink layer of printing works.

◆ By test, controls production technique efficiently, avoids loss of goods returns caused by bad quality.

◆ The specimens coating and receptor rub each other under specified speed and pressure load. Determine the abrasion of coating or ink layer by testing the decrement of coating concentration or decrement of coating thickness.

Main Technical Parameters

■ Motor Power:60W 220V 50Hz

■ Rubbing pressure:10±1 N (abrasion pad);10±1 N (weight)

■ Rubbing speed:5-95/min(stepless speed regulation)

■ Rubbing head area: 95mm (L) x 50 mm (B)

■ Rubbing Distance:60mm

(We also can offer special rubbing distance as 100mm,120mm and 155mm)

■ Rubbing times: 0~9,999

■ Specimen size: 270 mm (L) x 70 mm (B)

■ Overall dimension:275×305×340mm (length by width by height)

■ Weight:15Kg

Kesin Ovma Resiztansı

Characteristics

◆ Applicable in dry or wet rubbing or scuffing, wet bleed, transfer, wet smear and functional tests.

◆ Arc moving model, double testing station, high efficiency

◆ Manifold speeds, convenient and flexible.

◆ Micro computer controls, film front control panel

◆ LCD displays testing data

◆ Function of memory when power off, buzzer prompts automatically when test is finished.

◆ By test, controls production technique efficiently, avoids loss of goods returns caused by bad quality.

◆ The specimens coating and receptor rub each other under specified speed and pressure load.

Determine the abrasion of coating or ink layer by test the decrement of coating concentration or decrement of coating thickness.

Main Technical Parameters:

■ Rubbing pressure:8.9N (2lb),17.8N (4lb)

■ Rubbing speed: 21, 42, 85,106cpm

■ Rubbing motion: to-and-fro arc motion

■ Rubbing times: 0~999,999

■ No. of specimens: 1~2 pieces

■ Dimension: 485 mm (W)×390 mm (D)×230 mm (H)

■ Power: AC 220V 50Hz/60Hz

■ Net weight: 40 kg

■ Standards:ASTM D5264 TAPPI T830

■ Configuration Standard: Mainframe, test block 8.9N (2lb),test block 17.8N (4lb), Rubbing pad

■ Optional:Non-standard test block